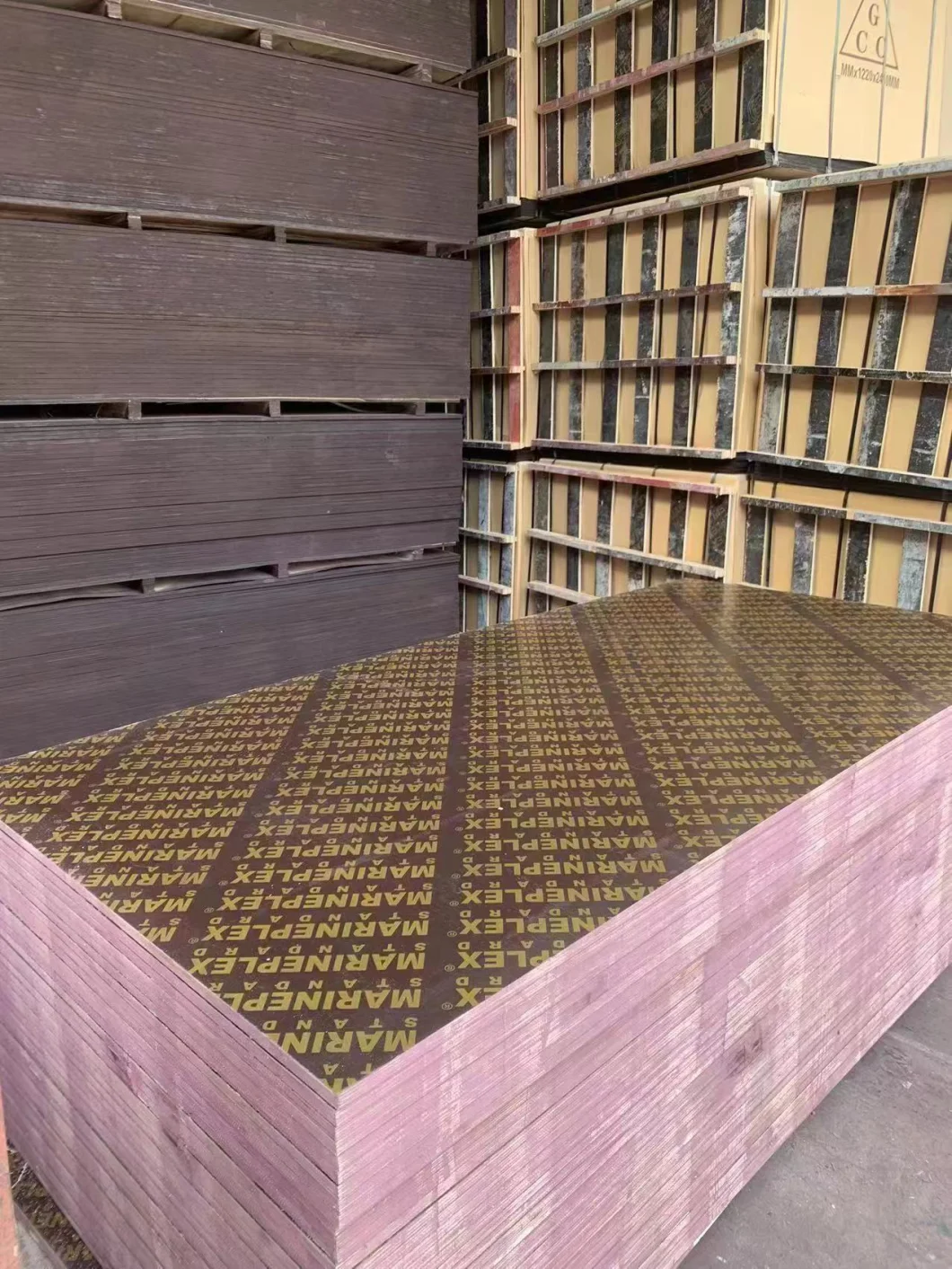

Black/Red/Brown/Green Film Faced Plywood Marine Plywood

Overview Package size per unit product 30.00cm * 30.00cm * 1.80cm Gross weight per unit product 3.000kg NOTICE:Here are

Basic Info

| Material | Poplar |

| Grain | Irregular Grain |

| Bonding Strength | Ⅲ(Nc) |

| Plywood Type | 13-Ply |

| Formaldehyde Emission Standards | E1 |

| Specifications | 1220*2440*18mm |

| Place of Origins | Shandong,China |

| Grade | Excellent Grade |

| Usage | Outdoor |

| Transport Package | Standard Exporting Package |

| Specification | 1220*2440*18mm or customized |

| Trademark | mulzza |

| Origin | Shandong, China |

| Production Capacity | 10000PCS/Month |

Packaging & Delivery

Package size per unit product 30.00cm * 30.00cm * 1.80cm Gross weight per unit product 3.000kgProduct Description

NOTICE:Here are only part of our products.If there's not be what you need,please contact me freely to get what you require.Thanks!

Product Description

| Product name | Hot Sale 1220X2440X12/15/17/17.5/18mm Film Faced Plywood for Construction |

| Core materials | poplar/eucalyptus/combi (hardwood + soft wood) |

| Size(mm) | 1220X2440mm,1250X2500mm,915X1830mm or as per customers' required specifications |

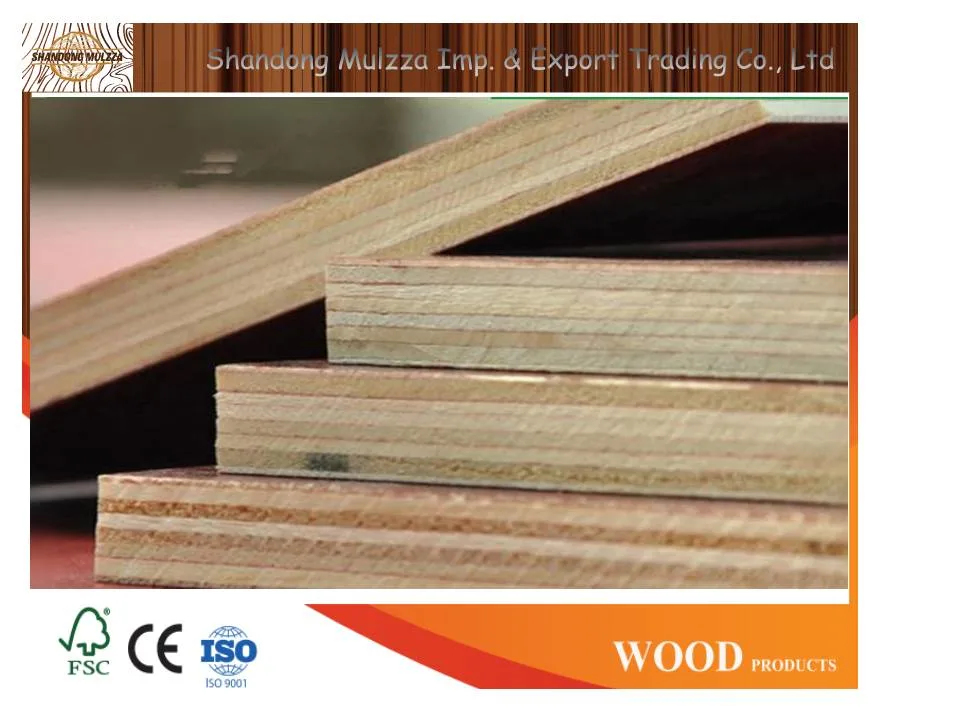

| Thickness | 8-30mm or as per your requirements |

| Thickness Tolerance | Length&Width:+/-2mmThickness:+/-0.2mmOr as per the clients' demand |

| Moisture | less than 10% |

| Face/Back(Film Color) | BLACK,RED,BROWN(WITH LOGO OR WITHOUT LOGO;DOUBLE-SIDE DECORATION),PP Plastic film |

| Grade | One time hot press,two times hot press etc. |

Finger joint core/Full core | |

| Usage | Construction Shuttering |

| Supply ability | 12000pieces/month |

| Price Term | FOB,CNF,CIF etc. |

| Payment Term | 30% T/T in advance,70% balance after the receipt of the scanning of B/L |

| L/C AT SIGHT | |

| Packing | Pallet packing&Loose packing |

| LOADING QUANTITY | 20'GP:8PALLETS |

| 40'GP:16PALLETS | |

| 40'HQ:18PALLETS | |

| MOQ | 1x20'GP |

| Glue | E0,E1,E2,MR,WBP,MELAMINE |

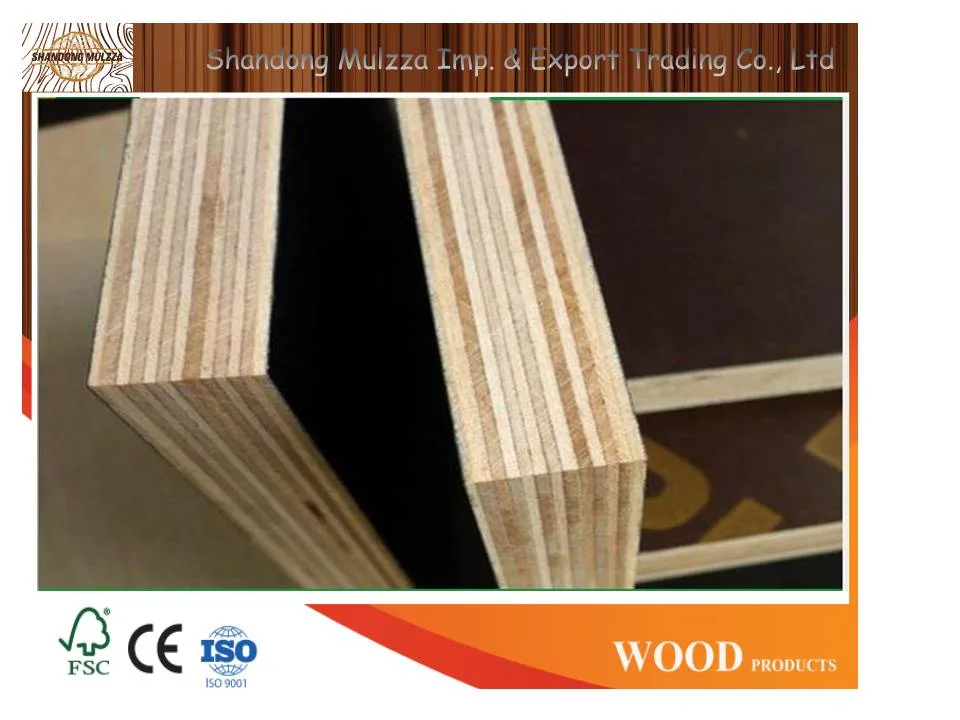

| Number of piles | 7 piles for 12mm;9 piles for 15mm;11 piles for 18mm; |

| The turnover times | 4-30; |

| Delivery time | 15-20 days after receive the deposit or original LC |

Production Process | Wood chip→ gluing → pave → pre-press →first hotpress → repair core→ first sanding → caot face andback veneer → second hot press → sanding again →cutting→ inspection sheet by sheet →packin |

Detailed Photos

Product Parameters

Film Faced PlywoodUsing quality poplar pieces,the whole core,no holes after being sawn,to ensure the tenacity of the construction shuttering.

From core to panel ,both using high concentration and high strength waterproof glue,core boards are coated with glue layer by layer,comprehensive adhesion,increasing bonding strength5~10%Thermal pressure is 120% of theoriretical pressure.Avoiding reducing the pressure to preserve the thicknessThe substrate is sanded twice(two molding) before being coated,to ensure the smooth and flatness of the surface,no grooves.

The turnover times is about 4-30.

Packaging & Shipping

Certifications

Contact US:Annie zhang

Address:502 ROW CULTURAL AND CREATIVE BUILDING TECHNICAL COLLEGE,SHOUGUANG CITY,262700,SHANDONG PROVINCE,CHINA

Website:mulzza.en.made-in-china.com

Send to us