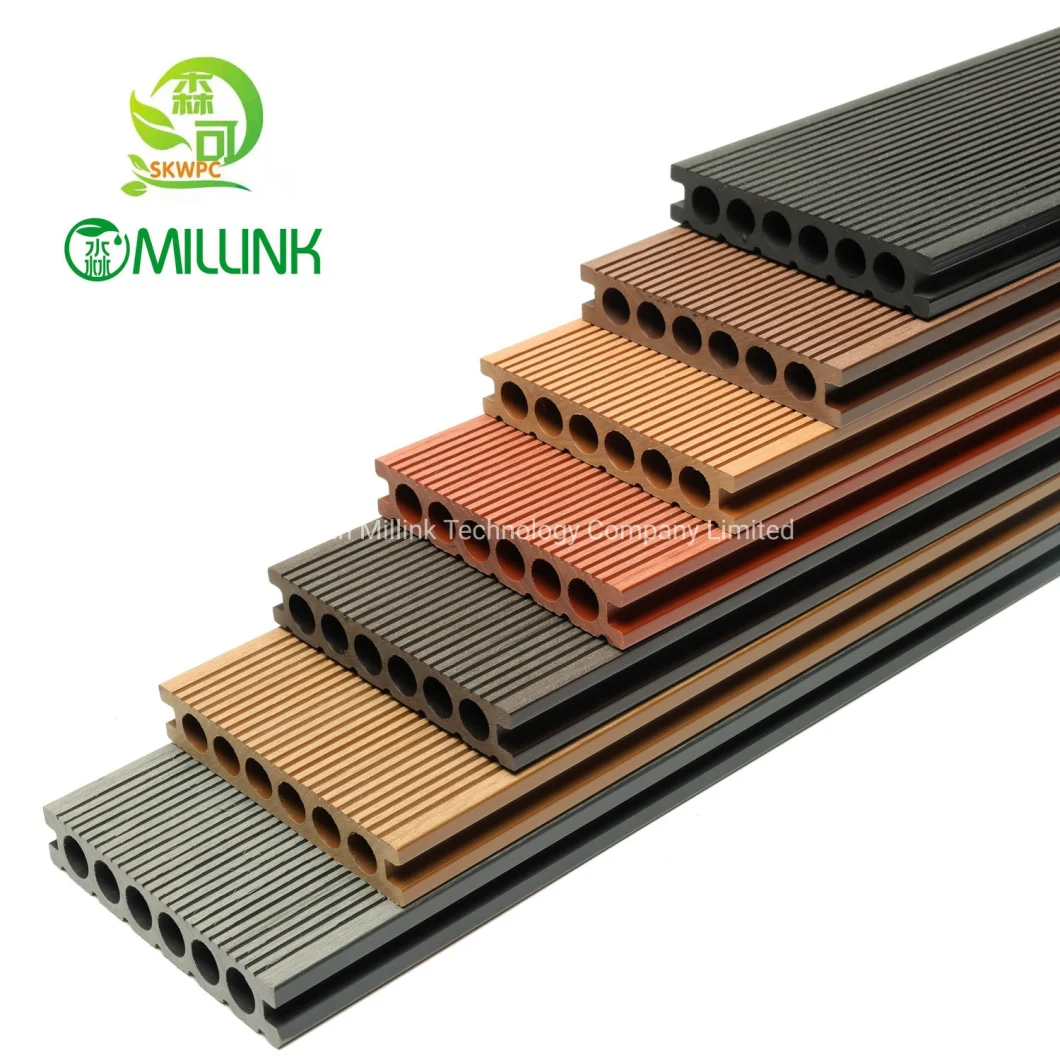

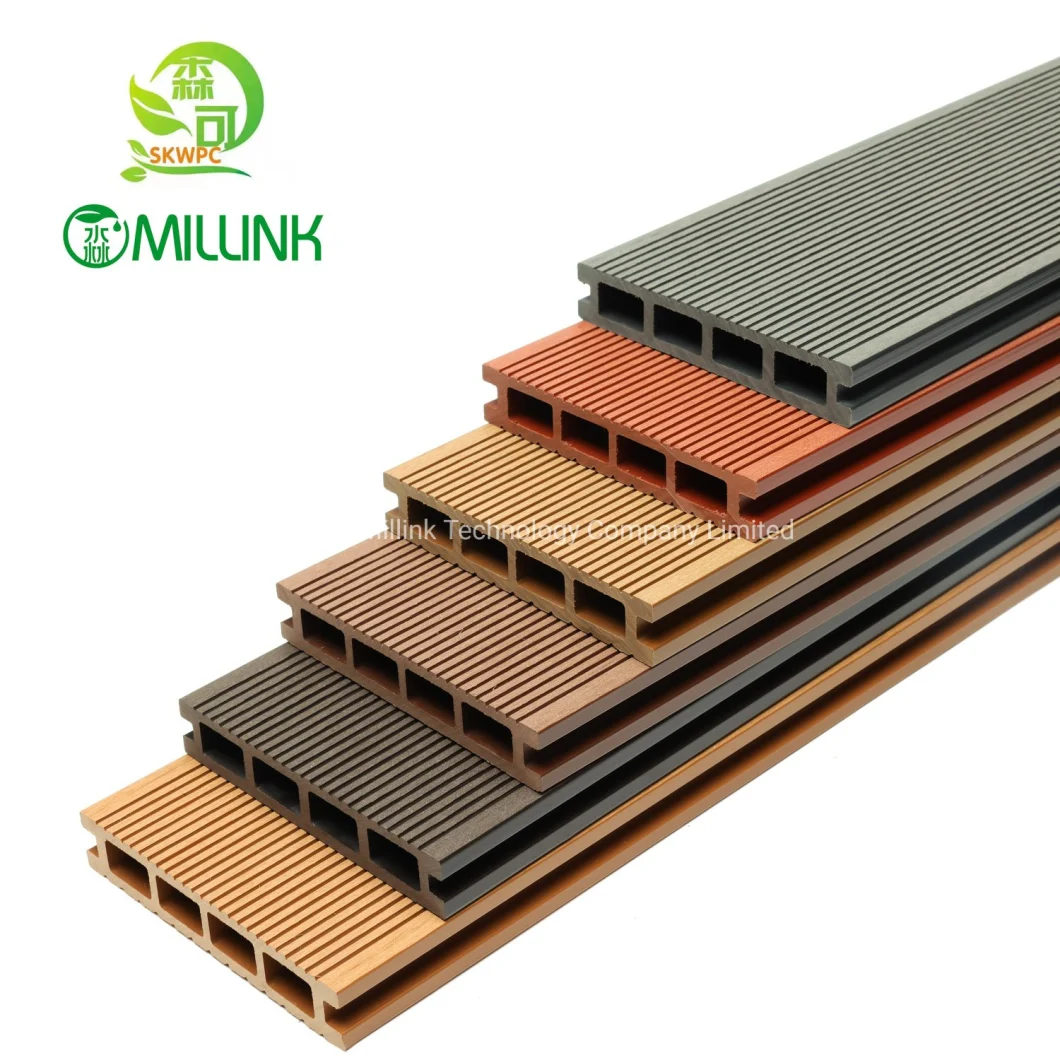

Anti Scratch Hollow Solid WPC Wood Plastic Deck Flooring / PE Flooring for Outdoor

W.P.C DECKING Specification of W.P.C Decking:Our FactoryPacking & Delivery:What is W.P.C ? Wood-plastic composites (WPCs

Basic Info

| Model NO. | H140x25 |

| Pattern | Wood Grain |

| Color | Red |

| Certification | CE |

| Usage | Household, Outdoor, Commercial |

| Customized | Customized |

| Transport Package | Pallet & Bundle |

| Specification | Customized |

| Trademark | Millink |

| Origin | China |

| HS Code | 3925900000 |

| Production Capacity | 120000 Sqm/Year |

Product Description

W.P.C DECKING

Specification of W.P.C Decking:Our FactoryPacking & Delivery:What is W.P.C ?

Wood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) (includes PE, PP, PVC etc.).Chemical additives seem practically "invisible" (except mineral fillers and pigments, if added) in the composite structure. They provide for integration of polymer and wood flour (powder) while facilitating optimal processing conditions.In addition to wood fiber and plastic, WPCs can also contain other ligno-cellulosic and/or inorganic filler materials.What is the advantages of W.P.C?

WPC do not corrode and are highly resistant to rot, decay, and Marine Borer attack, though they do absorb water into the wood fibers embedded within the material. They have good workability and can be shaped using conventional woodworking tools.WPCs are often considered a sustainable material because they can be made using recycled plastics and the waste products of the wood industry.One advantage over wood is the ability of the material to be molded to meet almost any desired shape. A WPC member can be bent and fixed to form strong arching curves. WPCS are manufactured in a variety of colours, another major selling point of these materials is their lack of need for paint.

How to produce the W.P.C?

What is the uses of W.P.C?

Wood-plastic composites are still new materials relative to the long history of natural lumber as a building material.The most widespread use of WPCs is in outdoor deck floors, but it is also used for railings, fences, landscaping timbers, cladding and siding, park benches, molding and trim, window and door frames, and indoor furniture.

Send to us